ScanPort™ is being launched by a group of Oklahoma professionals with national and international experience developing world-class technology.

They’ve spent their careers advancing energy, finance, logistics, and digital systems around the globe — and are now using that same expertise to strengthen healthcare where it matters most: at home.

ScanPort™ brings this technology together to focus on pediatric diseases and the long-term effects of COVID-19. It combines advanced digital scanning, a new form of artificial intelligence we call Digital Intelligence™, and straightforward Oklahoma practicality to see the body in new ways and catch problems early.

Robotic XRay | Digital MRI | PET|CT | 3D CT | Mammogram | Digital Ultrasound

Let’s take a look inside the home of these advanced digital scanning technologies.

Each ScanPod™ is built from a series of precision-engineered GreenBox™ modules that come together like building blocks to form a complete medical unit.

In the video below, you’ll see a single container become a fully functional ScanPod™, housing the world’s most advanced digital scanners within a structure designed for efficiency, privacy, and sustainability.

Inside the ScanPod™

This is where advanced digital scanning meets everyday care.

Each space within the ScanPod™ houses a specialized imaging system — from robotic X-ray to MRI, PET, CTs, and ultrasound — arranged for speed, safety, and comfort.

Children and adults can complete every scan in a single visit, with data streamed directly to physicians and researchers studying pediatric disease and Long COVID.

It’s a quiet, efficient environment built for precision and healing.

Let's take a Drone flight through the ScanPod™

The short video below illustrates a fly-through of a fully assembled ScanPod™ — a complete scanning and data environment built inside modular GreenBox™ units.

You’ll move from the scanning module itself to the comfort and support spaces designed around it — locker rooms and restrooms where patients can change into scanning attire, a small refreshment area, and a welcoming reception and conference zone with high-tech video walls.

Further inside, you’ll see the secure data center where scan information is processed and stored, along with specialty rooms for video consultations with physicians anywhere in the world.

These spaces can also host immersive, large-scale displays for reviewing scans in detail.

Every module serves a purpose — patient care, data integrity, or collaboration — all connected in one efficient structure dedicated to early detection and advanced diagnostics.

The Digital Twin:

Seeing the Whole Human

Each scan from the ScanPod™ captures a unique layer of the body — motion, flow, structure, metabolism, and density.

When these layers are stacked together, they form a complete digital model of how a person’s body actually works.

This model is called a Digital Twin — a precise, living reference that lets physicians compare organ systems side-by-side, track change over time, and identify early signs of disease that traditional scans often miss.

For patients, it means earlier answers and clearer decisions.

For researchers, it provides the anonymized data needed to study medium and long-term, as well as emerging pediatric conditions and patterns in Long COVID.

Each Digital Twin remains fully private, stored under strict security and accessible only to authorized medical teams or, by consent, to ongoing research programs.

The Digital Twin is the bridge between today’s diagnostics and tomorrow’s Digital Intelligence — the point where understanding begins.

The HealthPort™ concept began as a series of destination campuses across Oklahoma — places where people could come for a complete picture of their health in a single visit. Each facility was envisioned as a multi-disciplinary center combining advanced scanning, research, and renewal — a full experience rather than a single appointment.

Those early designs taught us what was possible: how to bring world-class imaging, AI, and human care together in one environment. From that foundation came ScanPort™ — a more compact, modular version of the same vision, designed for faster deployment in metro and suburban communities while retaining the HealthPort™ principles of integration, efficiency, and care.

ScanPort™ Corner

At first glance, it might look like a single modular scanning facility — a compact structure built from GreenBox™ units with precision and purpose.

But a closer look reveals something more.

By extending these modules outward to include office and storage spaces, the design begins to take shape — the suggestion of a corner, the beginning of a larger form.

Each container serves a role: scanning, administration, data handling, or support.

Together they create a rhythm of structure that feels intentional, expandable — almost as if this corner is part of a greater whole waiting to be seen.

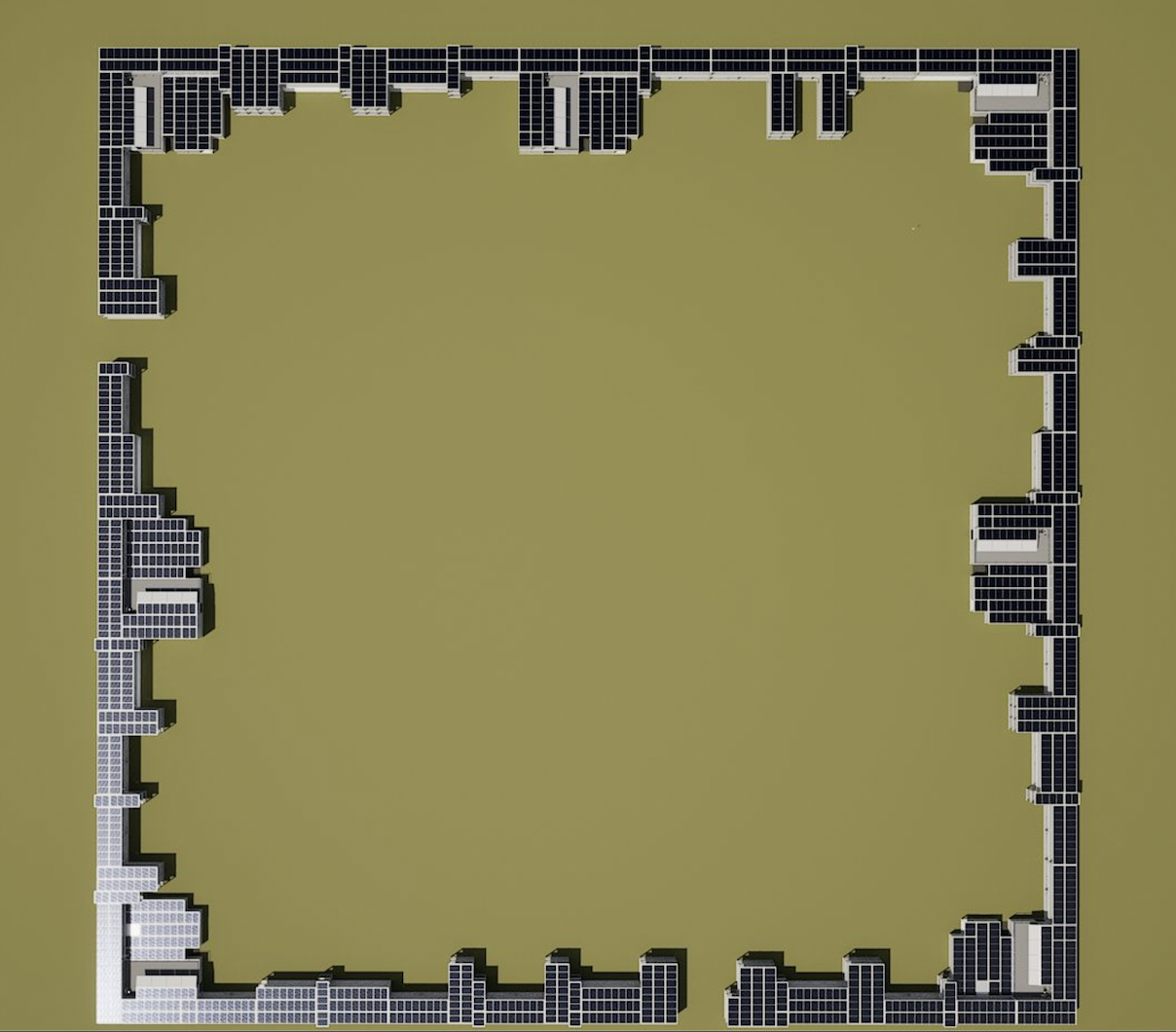

The ScanPort™ site combines precision engineering with community design.

Seven ScanPods™ define its geometry — one at each corner and three along the perimeter — with the main entrance on the fourth side.

Nineteen-foot-high exterior walls enclose the site, forming a secure compound built from ballistic- and kinetic-rated steel.

Inside, the perimeter walls do double duty, housing shops, restaurants, and offices that give the site a small-town atmosphere and everyday life.

Within the secure boundary lies a landscaped plaza with parks, fountains, solar-covered parking, and shaded walking paths.

Visitors can stay overnight, enjoy local dining, or take in community events while completing their scans in less than 24 hours.

Each ScanPort™ is designed to feel familiar, safe, and alive — a place where healthcare and daily life meet in one intelligent, connected space, a place of recovery and healing.

Each GreenBox™ unit begins as a precision-engineered 8×40-foot intermodal container—320 square feet of high-strength, corrosion-resistant steel. Two connected as a companion pair form a 640-square-foot floorplate, ready for interior customization: two single offices, a shared suite, or two-room office with kitchen and bath. Above, a second level can provide secure, walk-up storage or additional workspace. Every GreenBox™ is designed for rapid transport, easy stacking, and lifetime durability—the true DNA of ScanPort™ construction.

Core Module - From these core modules come larger, multi-use structures. Here you can see a four-unit (2×2) configuration with integrated stairwell and elevator—built to ADA standards and offering bullet- and blast-resistant exteriors. These same cores can become clinics, shops, offices, or living suites, depending on finish and fit-out. Every unit is designed to connect laterally and vertically, giving developers near-limitless flexibility to create safe, energy-efficient environments that evolve with community needs.

The ScanPort™ Site — Secure, Scalable, and Self-Sustaining Seen from above, each ScanPort™ forms a 10+/- acre self-contained community of care. Seven ScanPods anchor the corners and sides, forming a secure perimeter with solar roofs, kinetic shielding, and integrated data flow. Inside lies a flexible commons — designed for parks, fountains, small shops, and gathering areas. This is health infrastructure built for people, not institutions.

ScanPortOKC is a $650 million national prototype under development in Oklahoma City metro — one of the first U.S. facilities designed to enable full body scanning in one visit, bringing together seven advanced digital scanning modalities in a single 10-acre campus, to build an AI enabled DigitalTwin™ of each participant.

With a focus on Pediatric Diseases

and long-term effects of COVID-19.

Every community has families who are struggling with pediatric conditions and the long-term effects of Long COVID. ScanPort’s 501(c)(4) foundation—supported through the ScanKids™ mission—exists to give those families access to better resources and long-term support. And now, under current federal incentives, individuals can use their tax offsets to help build the energy and scanning infrastructure that will support these programs for years to come. The entire site is designed to operate Beyond Net Zero, producing more clean power than it consumes—and directing that surplus to benefit children and youth through ScanKids™.

In 1984, we helped pioneer one of the earliest custom applications of the 40′ ISO Intermodal Container. Long before modular construction became mainstream, we used this form factor to build self-service storage units that still look modern 40 years later.

At the time, these units qualified for a 10% investment tax credit and five-year depreciation, and major financial institutions acquired them specifically for those incentives.

Today, we return to that same proven platform — but with a far more advanced mission.

The ISO form factor provides the ideal foundation for combining:

clean-energy generation,

thermal storage and transfer,

micro-AI compute nodes,

high-security digital and physical infrastructure,

high-speed global connectivity, and

the most advanced multi-modality digital scanning systems in the world.

Each GreenBox™ captures and manages thermal energy, converts it to clean electricity, and operates high-density AI systems. These engineered attributes enable each GreenBox™ to qualify as a §48E Qualified Facility.

Federal Incentives (Clean Electricity Program)

GreenBox™ units ordered with a 10% deposit before December 31, 2025 may be eligible for:

100% Bonus Depreciation in 2025, and

40% Clean Electricity Investment Tax Credit (ITC) in 2026,

assuming domestic-content thresholds and final IRS guidance are met.

Purchasers who adopt our domestic + international operating framework may also qualify for a 14.25% U.S. federal tax rate on a significant portion of revenue generated by the GreenBox™.

For U.S. taxpayers in the highest bracket, a USD $1,000,000 GreenBox™ ordered in 2025 may produce federal tax incentives exceeding USD $800,000 across bonus depreciation and ITC.

Five-Year Giving Opportunity

Holding a GreenBox™ for the five-year federal recapture period creates an opportunity to gift the unit to a qualified 501(c)(4) non-profit supporting the ScanKids™ initiative, qualifying for additional charitable contribution tax offsets.

Expanding the Qualified Facility Envelope

Each individual GreenBox™ qualifies as its own §48E Qualified Facility.

Combining two units into a Companion Container Set creates a Pod-class Qualified Facility with additional energy-property capacity.

Adding a Scan Companion Container Set enables installation of advanced digital imaging systems, as illustrated, expanding the thermal-electric envelope of the facility and may qualify the combined unit for 30–40% ITC in addition to 100% bonus depreciation on the full system.

We invite you to become a part of this new Pediatric Diseases | Long COVID initiative as it moves from concept to healing.

A New Dawn for Community Health

As the sun rises over each ScanPort™, the system quietly powers itself — solar arrays capturing light, cooling systems balancing entropy, and data syncing securely to local medical teams.

It’s not just a building — it’s a living network, designed to restore health, dignity, and hope right where people live.